Understanding the Role of Sprockets in Steel Industry Machinery

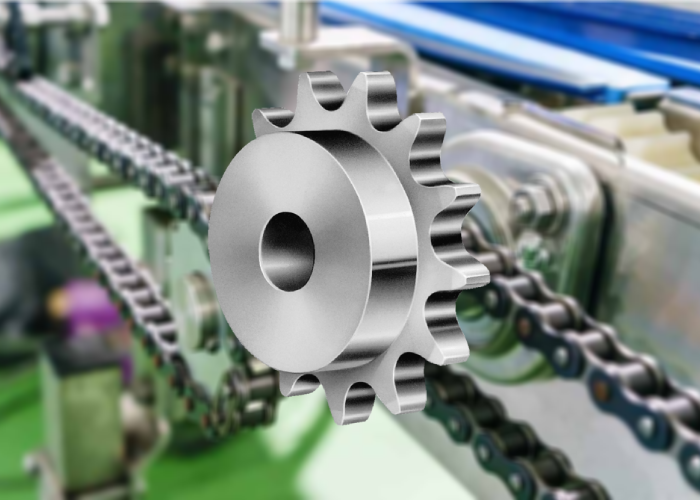

Expert Engineering Co. is a leading sprocket manufacturer for steel industrial needs, delivering high-quality products that meet the specific demands of steel production. The steel industry is the backbone of modern manufacturing, and it relies on a wide range of components to keep its operations running smoothly. Among these essential components, sprockets play a critical role in the transportation and processing of materials within steel plants. These mechanical parts are involved in almost every stage of the production process, from moving raw materials to managing conveyor systems. In this blog, we will explore the importance of sprockets in the steel industry, the benefits they bring, and how Expert Engineering Co. supports the industry with its manufacturing capabilities. Understanding the role of sprockets helps to shed light on their contribution to making the steel production process more efficient, reliable, and precise.

Understanding the Steel Industry's Sprocket Needs

The steel industry relies heavily on high-quality sprockets to facilitate the efficient movement and processing of materials. Understanding the specific needs and applications of these components is important for manufacturers. By aligning their products with industry demands, companies like Expert Engineering Co. can deliver effective solutions that improve operational efficiency.

1. Analyze the Steel Manufacturing Process

- Identify the Key Applications of Sprockets in the Steel Industry: Sprockets are important in conveyor systems, transporting raw materials such as iron ore and coal. They also play an important role in cranes and hoists, facilitating the movement of heavy steel components throughout the manufacturing process.

- Understand the Performance Requirements and Specifications for Sprockets Used in Steel Production: Sprockets must endure high loads and resist wear, given the harsh conditions in steel manufacturing. They require precise engineering to make sure alignment and effective power transmission, making customization essential for various applications.

2. Assess the Competitive Landscape

- Research Existing Sprocket Manufacturers Serving the Steel Industry: Analyzing competitors helps identify their strengths and weaknesses, offering insights into common product offerings. Understanding the landscape allows for better positioning in the market.

- Identify the Market Gaps and Opportunities for Your Business: By exploring current suppliers' limitations, manufacturers can uncover opportunities for specialized sprocket designs. Tailoring products to meet specific needs in steel production can lead to a competitive edge in the industry.

Importance of Sprockets in the Steel Industry

sprockets are fundamental to the proper functioning of machinery in the steel industry. They facilitate the transfer of power and motion between shafts, allowing machinery to operate smoothly and efficiently. Whether it's moving raw materials through conveyor systems or operating cranes and other heavy equipment, sprockets are responsible for confirming the smooth movement of materials at every stage of steel production. Without them, the entire process would become inefficient, resulting in costly delays and disruptions. The right sprockets can significantly reduce downtime, increase productivity, and help maintain the overall efficiency of the steel plant.

In the steel industry, sprockets are used in a variety of processes, each requiring a different type of sprocket depending on the machine's design and the load it handles. For instance, conveyor systems rely on sprockets to move large quantities of raw materials, while cranes need them to lift and transport heavy steel slabs. Expert Engineering Co. understands these needs and manufactures sprockets that can handle the unique requirements of each application, making them an indispensable part of the steel production process.

Uses of Sprockets in the Steel Industry

- Material Transport: Sprockets are integral to conveyor systems, facilitating the movement of raw materials like iron ore, coal, and finished steel products throughout the manufacturing process.

- Lifting Mechanisms: They are essential in cranes and hoists, allowing for the efficient lifting and transportation of heavy steel components within the plant.

- Bucket Elevators: Sprockets support bucket elevators that vertically transport materials, confirming smooth and efficient handling of bulk materials at different production levels.

- Rolling Mills: In rolling mills, sprockets manage the movement of steel as it is processed, shaped, and cut, playing a critical role in maintaining production flow.

- Power Transmission: Sprockets efficiently transfer power and motion between machinery components, make sure easy operation in various applications across the steel production line.

- Customization: They can be designed to fit specific machinery requirements, allowing for personalised solutions that increase operational efficiency and performance.

Benefits of Using Sprockets in the Steel Industry

Incorporating high-quality sprockets into steel industry operations brings numerous advantages. Below are some of the key benefits:

- Efficiency: Sprockets help reduce energy loss during power transmission, resulting in more efficient operations and lower energy costs for steel plants.

- Durability: Sprockets are designed to withstand heavy loads and operate in extreme conditions, making them durable and long-lasting components in the harsh environment of steel manufacturing.

- Capability: Sprockets can be configured in different ways to meet the specific needs of various machines, allowing them to be used across a wide range of applications in steel production.

- Precision: Sprockets are engineered to provide precise control over the movement of machinery, which is important in maintaining the accuracy and consistency of steel production processes.

- Low Maintenance: High-quality sprockets reduce the need for frequent repairs or replacements, minimizing downtime and allowing for continuous operation in steel plants.

Manufacturing and Supply Capabilities of Expert Engineering Co.

Expert Engineering Co. is well-equipped to meet the growing demand for sprockets in the steel industry. Based in Ahmedabad, Gujarat, the company’s innovative manufacturing facility produces sprockets that meet the highest quality standards. The production process involves advanced technology and rigorous quality control to make sure that each sprocket is durable, reliable, and capable of performing in the most challenging industrial environments. With a strong presence in key steel production hubs like Hajira, Surat, and distribution capabilities that extend to other major cities such as Jamshedpur, Rourkela, Bhilai, Vijaynagar, Dolvi, and Vasind, Expert Engineering Co. has positioned itself as a leading supplier of sprockets in India. The company’s focus on precision engineering and quality assurance confirms that every sprocket meets the stringent demands of steel manufacturing.

Conclusion

Sprockets are indispensable in the steel industry, providing the power and precision needed to keep production processes running efficiently. Expert Engineering Co. stands out as a leading sprocket manufacturer, offering products that are durable, reliable, and personalised to meet the varies needs of steel plants. By focusing on high-quality materials, precise engineering, and innovative designs, the company has established itself as a trusted partner for steel manufacturers across India. As the steel industry continues to evolve, the demand for high-performance sprockets will only grow, making Expert Engineering Co.'s products essential for driving productivity and innovation in the steel manufacturing landscape.

Our Range of Industrial Equipment:

For more information about to explore the complete range of products, please call us at +91 794897977 or email us at experteng@hotmail.com. We would be happy to help you find the perfect solution for your industry’s needs.

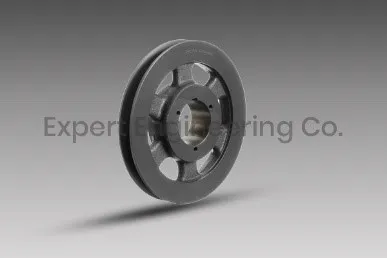

# Conveyor chain Manufacturer for sugar Industry | Sprocket Manufacturer for steel Industry | Pulley Manufacturer for boat Industry | Gear Manufacturer for oil & gas Industry | Shaft Manufacturer for agriculture Industry | Roller chain Manufacturer for textile Industry | Link chain Manufacturer for shipyard Industry | Conveyor sprocket Manufacturer for steel Industry