Sprockets in the Fertilizer Industry

The agricultural sector is not complete without the fertilizer industry, which is very important for boosting crop growth and productivity. This industry needs dependable and efficient equipment to keep things running smoothly, and sprockets are essential to material handling and power transmission systems. Expert Engineering is one of the top producers of industrial sprockets in India, offering a broad selection of superior sprockets that are specifically designed to satisfy the various demands of the fertilizer sector and other related industries.

Understanding Sprockets and Their Role in Industry

Sprockets are mechanical components that move rotary motion between two shafts when used with a chain. In a variety of industries, like the fertilizer business, Expert Engineering industrial sprockets are utilized to drive conveyor belts, improve material handling, and deliver power effectively. In order make sure the smooth operation of the conveyor systems that are important to the manufacturing of fertilizer, sprockets are made out of a wheel with teeth that connect with a roller chain. These sprockets are perfect for industries where heavy weights and extended operating hours are typical as they are built to last and are composed of materials that don't easily break.

The Importance of Sprockets in the Fertilizer Industry

The fertilizer industry demands efficient machinery that can handle bulk materials like fertilizers, raw materials, and finished products. Sprockets play a key role in this process, driving conveyor belts that transport materials across different stages of production, from raw material processing to packaging. Industrial sprockets are crucial to maintaining continuous, efficient production, as they help reduce friction and mechanical resistance, making sure that machinery operates at optimal levels. In fertilizer plants across Vadodara, Gujarat, and other parts of India, such as Kanpur, Gorakhpur, and Bareilly, high-quality sprockets are essential components. By offering precise, durable, and efficient sprockets, Expert Engineering helps companies in the fertilizer sector achieve improved operational efficiency.

Types of Sprockets Used in the Fertilizer Industry

The fertilizer industry utilizes different types of sprockets, each designed to serve specific functions within the production process. Expert Engineering as a premier industrial sprocket manufacturer in Ahmedabad offers a complete range of sprockets that meet the industry’s demanding requirements.

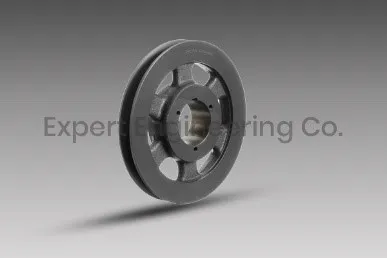

Roller Chain Sprockets

Roller chain sprockets are among the most widely used types of sprockets in the fertilizer industry. These sprockets are designed to work with roller chains, providing a smooth transfer of motion that make sure conveyor systems function easily. Roller chain sprockets are made from durable materials like hardened steel to withstand heavy loads and harsh environmental conditions.

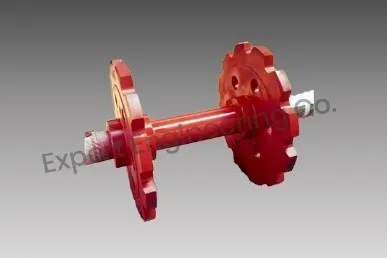

Conveyor Sprockets

Conveyor sprockets are specifically designed for conveyor systems that transport bulk materials like fertilizers. These sprockets are engineered to handle the heavy-duty demands of industrial environments, making them ideal for use in the fertilizer sector. With conveyor sprockets, companies can maintain the efficiency and quality of their material handling systems, which are critical to uninterrupted production.

Duplex and Triplex Sprockets

Duplex and triplex sprockets are multi-strand sprockets used in applications where high torque and heavy loads are required. These sprockets feature two or three rows of teeth, offering increased power transmission capacity. In fertilizer plants, duplex sprockets and triplex sprockets are used in heavy-duty machinery that requires extra strength to handle large volumes of materials.

Key Features of Expert Engineering Sprockets

As a leading industrial sprocket supplier in India, Expert Engineering focuses on quality, precision, and durability. Their sprockets are known for several key features:

- Durability: The sprockets produced by Expert Engineering are built to last. Made from high-grade materials, they can withstand the harsh operating conditions typically found in the fertilizer industry, such as exposure to corrosive substances, heavy loads, and extended operational hours.

- Precision Engineering: Precision is important in manufacturing sprockets that make sure smooth power transmission. Expert Engineering uses advanced manufacturing techniques to create sprockets that are perfectly aligned and balanced, reducing damage on chains and machinery.

- Customization: Each industry has its unique requirements, and Expert Engineering offers sprockets that are customized to meet the specific needs of the fertilizer industry. Whether it's roller chain sprockets, conveyor sprockets, or duplex sprockets, the company make sure that each product is engineered to provide optimal performance.

- Efficient Power Transmission: The sprockets designed by Expert Engineering are known for their ability to deliver efficient power transmission, which is important in maintaining the smooth operation of conveyor systems and machinery in fertilizer production facilities.

- High Load Capacity: Fertilizer plants often require machinery capable of handling large quantities of raw materials and finished products. The industrial sprockets supplied by Expert Engineering are designed to handle high loads without compromising performance.

Applications of Sprockets in the Fertilizer Industry

In the fertilizer industry, sprockets are used in various applications, including:

- Conveyor Systems: Sprockets are frequently used in conveyor systems that move both completed fertilizers and raw materials including phosphates, potash, and nitrogen compounds. Conveyor sprockets make sure that materials are transferred effectively from one stage to the next and contribute to the easy operation of these systems.

- Packaging Machinery: The fertilizer needs to be packaged for distribution after it has been prepared and processed. Conveyor belts that move fertilizer bags and containers through the packing process are driven by sprockets in packaging gear.

- Mixing and Blending Systems: Fertilizer production involves the mixing of different chemical compounds. Sprockets are used in the machinery that powers these mixing and blending systems, making sure that the ingredients are properly combined.

Why Choose Expert Engineering?

- Extensive Range of Products: Expert Engineering offers a complete selection of sprockets, including roller chain sprockets, conveyor sprockets, duplex sprockets, and triplex sprockets. This variety make sure that customers can find the perfect solution for their specific application.

- Industry Expertise: With years of experience serving the fertilizer industry, Expert Engineering understands the unique challenges faced by manufacturers. Their sprockets are designed to meet these challenges, offering quality, efficiency, and long-lasting performance.

- Commitment to Quality: Quality is the cornerstone of Expert Engineering approach to sprocket manufacturing. Each sprocket undergoes rigorous testing to make sure that it meets the highest standards of durability and precision.

- Global Reach: While based in Ahmedabad, Expert Engineering supplies sprockets to companies across India, including major industrial hubs like Vadodara, Kanpur, Gorakhpur, and Bareilly. Their products are trusted by fertilizer manufacturers across the country.

Conclusion

Expert Engineering is a leading supplier of high-quality sprockets that are designed for durability, precision, and efficient power transmission. In the fertilizer industry, the role of sprockets cannot be understated. From driving conveyor belts to facilitating the movement of bulk materials, industrial sprockets are essential components of the machinery used in fertilizer production. With their wide range of sprocket types, including roller chain sprockets, conveyor sprockets, duplex sprockets, and triplex sprockets, Expert Engineering make sure that fertilizer manufacturers have access to the best industry for their operational needs.

Our Range of Industrial Equipment:

For more information about our high-quality sprockets and to explore the full range of products for the fertilizer industry, please call us at +91 9725054977 or email us at experteng@hotmail.com. Our team at Expert Engineering is ready to assist you with all your sprocket needs.

# Conveyor Chain Manufacturer & Supplier | Conveyor Chain Manufacturer & Supplier | Railway Track Accessories Manufacturer & Supplier | Link Chain Manufacturer & Supplier | Industrial Sprocket Manufacture & Supplier