Gear Manufacturer

Gears are important mechanical components found in a wide range of systems, including sophisticated clocks and heavy-duty automobile machinery. They convey motion and power, making them important for both simple and complicated machines. As a gear maker, understanding the subtleties of gear production is important for producing high-quality components that fulfill the needs of different sectors. We will look at several types of gears, the materials utilized, and the production procedures involved. We will also highlight Expert Engineering's function as a leading gear manufacturing company selling high-quality gears throughout India, including Vadodara, Surat, Ahmedabad, and other areas.

Types of Gears

Gears come in a variety of shapes and arrangements, each designed to perform a certain function. Understanding these categories is critical for manufacturers and engineers who must match the proper equipment to the intended application.

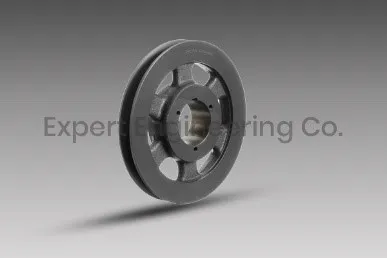

Spur Gears

Spur gears are the most common type of gear, with straight teeth set on parallel shafts. They are used to transmit motion between two shafts and are commonly found in clocks, washing machines, and even automobile transmissions. Expert Engineering manufactures high-quality spur gears that are both strong and efficient for a variety of applications.

Helical Gears

Helical gears, unlike spur gears, have teeth cut at an angle, resulting in smoother and quieter operation. They are suited for high-speed applications and can withstand higher loads due to their overlapping teeth. Many industries use helical gears for automotive gearboxes and conveyor belts, and gear providers such as Expert Engineering supply these gears to a variety of industries.

Bevel Gears

Bevel gears are used to modify the direction of a shaft's rotation. They are normally installed on shafts spaced 90 degrees apart. In autos and other machines, these gears are used in differential drives to shift the direction of power. A skilled gear manufacturing company understands the precision required in producing bevel gears, especially for high-torque systems.

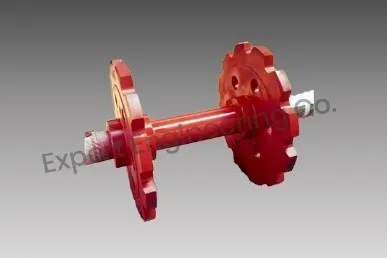

Worm Gears

Worm gears are outstanding in that they may deliver a lot of torque while taking up little space. They are made up of a worm (similar to a screw) and a gear. Elevators and conveyor systems are two examples of applications that use these gears to reduce speeds significantly. Worm gear manufacturers, such as Expert Engineering, specialize in providing dependable worm gears for industrial automation and heavy machinery.

Rack and Pinion Gears

This gear system consists of a rack (a straight gear) and a pinion (a tiny cylindrical gear). It converts rotational motion to linear motion, making it perfect for vehicle steering mechanisms. Expert Engineering, a gear manufacturer in India, provides high-quality rack and pinion systems to the automotive and manufacturing industries.

Materials Suitable for Making Gears

The material used to manufacture gears has a direct impact on its performance, durability, and applicability. Gear materials have evolved over time, increasing their strength and efficiency. As a gear maker, selecting the correct material is crucial for making dependable gears.

Cast Iron

Cast iron, known for its exceptional machinability and wear resistance, is commonly utilized to manufacture gears that must withstand significant loads without deforming. Its high compressive strength makes it ideal for heavy-duty applications, like as construction machinery.

Steel

Steel is one of the most popular materials used in gear manufacturing due to its strength, toughness, and versatility. It is often alloyed with other materials to enhance properties like hardness and corrosion resistance. Gear suppliers prefer steel gears for automotive, industrial, and power transmission applications.

Copper Alloy

Copper alloys, such as brass and bronze, have good wear resistance and are commonly used in worm gears when lubrication is crucial. These alloys are also corrosion resistant, making them ideal for gears used in extreme situations, such as maritime applications.

Bronze

Copper alloys, such as brass and bronze, have good wear resistance and are commonly used in worm gears where lubrication is required. These alloys are also corrosion-resistant, making them ideal for gears used in hostile situations such as maritime applications.

Plastics

Although not as strong as metals, plastics are employed in gear production for low-load applications where noise reduction and corrosion resistance are vital. Plastic gears are lightweight and affordable, making them perfect for use in consumer devices like as printers and toys.

Applications of Gears

Gears are widely used across sectors, making them essential components in many mechanical systems. The following are some significant sectors where Expert Engineering provides gears:

Automotive Industry

Gears play an important role in automobiles, from managing steering systems to power transfer in engines. Expert Engineering provides automotive industries with strong spur gears and helical gears that make sure excellent vehicle performance without the need for high-speed modification.

Factory Automation

In factory automation, gears are essential for efficiently transferring power throughout machinery. Worm gears, bevel gears, and rack and pinion systems are commonly employed in conveyor systems, which reduces the complexity of automation. Expert Engineering, a famous gear manufacturer in India, offers gears to manufacturing hubs such as Vadodara, Surat, and others.

Construction Equipment

Heavy-duty construction machinery, such as cranes and bulldozers, use gears to transmit power. Cast iron and steel gears are frequently chosen for their strength and longevity in these applications.

Marine Industry

The marine industry employs gears in ship engines and other mechanical systems. Bronze and steel gears are widely utilized due to their corrosion resistance and ability to handle high torque.

Expert Engineering: Gear Manufacturer

Expert Engineering, a leading gear manufacturer in India, has built a reputation for creating high-quality gears for a wide range of sectors. From spur gear manufacturers to worm gear manufacturers, we meet all of your gear-related needs with precision and competence. Our goods are widely used in Vadodara, Surat, Ahmedabad, and other industrial centers around India.

Our modern manufacturing facility makes sure that all of the gear we make fulfills the highest quality and performance standards. Whether you need gears for factory automation, automotive applications, or heavy machinery, Expert Engineering has the experience and skills to deliver.

When you choose Expert Engineering, you are selecting a gear manufacture that prioritizes precision, quality, and customer satisfaction. Whether you need spur gears, worm gears, or unique solutions, we're here to help you throughout India, from Vadodara to Surat and beyond.

Our Range of Industrial Equipment:

For more information about gears or to explore our range of products, please call us at +91 9825677909 or email us at experteng@hotmail.com. Let Expert Engineering help you find the perfect solution for your gear needs.

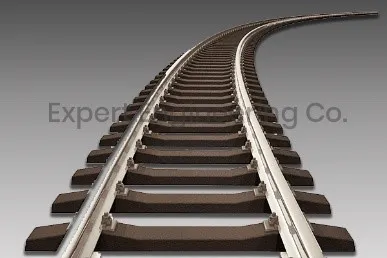

# Conveyor Chain Manufacturer & Supplier | Conveyor Chain Manufacturer & Supplier | Railway Track Accessories Manufacturer & Supplier | Link Chain Manufacturer & Supplier | Industrial Sprocket Manufacture & Supplier